During the last few weeks, we have dealt with the life cycle and the recycling of aircraft as part of our project “Project Website”. In Addition, we have researched an environmentally-friendly alternative energy and a calculator with that you can determine your own ecological footprint. In order to give additional expression to our work, we conducted an interview with an employee from the aircraft sector in order to bring in a professional opinion.

1. Lifecycle

[Selfmade Drawing]

1.1 Design

The aircraft design process is the engineering design process by which aircraft are designed. These depend on many factors such as customer and manufacturer demand, safety protocols, physical and economic constraints etc. For some types of aircraft the design process is regulated by national airworthiness authorities (CH: Bundesamt für Zivilluftfahrt).The design process starts with the aircraft’s intended purpose. Commercial airliners are designed for carrying a passenger or cargo (Fracht) payload, long range and greater fuel efficiency where as fighter jets (Militärflugzeug) are designed to perform high speed maneuvers and provide close support to ground troops. One of the most important requirement for airplane designers is reduction of weight – build something that has all the functional requirements while weighing as little as possible within reasonable cost, of course. Less weight means less engine thrust (Triebwerk Schubkraft) is needed, which means less fuel is burned. As a result of this, the airline makes more money.

1.2 Sell

The largest aircraft manufacturers are Airbus and Boeing. In 2015, Airbus generated a profit of $ 64.5 billion USD, while Boeing generated a profit of $ 96.11 billion USD.

>Source [de.wikipedia.org (Airbus), de.wikipedia.org (Boeing)]

1.3 Manufacturing

The use of recyclable materials in manufacturing have helped reduce the ecological impact due to aircraft.

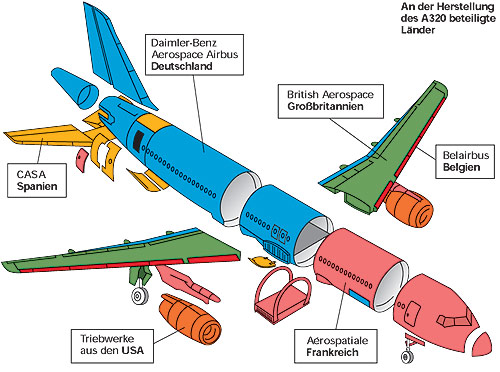

As you can see in the picture below. The manufacturing process is worldwide. Does this need to be done like this? Isn’t it better to produce it in one country? In our opinion it’s a waste of energy because of the transportation for the materials this also causes a lot of air-pollution.

And this could be eliminated, when the big manufactures are producing in one country. This will also help the locals. New worplaces will establish and they might have another perspective how to build an optimal Airplane. What do you think? Is this the right way? Let us know! we kindly ask you to write your ideas in de comment section below.

1.4 Recycling of Airplanes

Today’s air traffic generates a considerable sum. It is also irrelevant whether an aircraft is at all suitable for flight or not, because even an old, non-flightable (fluguntauglich) aircraft is a gold mine for some companies. The reason for this are precious raw materials such as aluminum, titanium and copper, which can be recycled during the recycling of aircraft. But this gold mine is difficult to achieve, since recycling involves certain problems. Aircraft can not be parked in Europe, for example, in Africa or America. You have to dismantle them as quickly as possible so that no corrosive process (Rostprozess) occurs.This would rust the metal. In addition, older aircraft models have the problem of recycling aluminum-lithium alloys (Aluminium-Lithium-Legierungen). Research programs are currently examining how this material can be disposed of and whether it is possible to recycle.

>Ideas: [https://www.recyclingnews.info]

[faz.net]

2. Solar Impulse

Air traffic has become indispensable to us people in our time. In 2015, 37.6 million flights were counted worldwide. As a result of the current phase of globalization, this figure will continue to rise and also the pollution of the environment by carbon dioxide emissions. A significant technological leadership has already been achieved by two pilots (Bertrand Piccard and André Borschberg) flying from Nagoya to Hawaii with a solar-powered aircraft. The solar flight lasted 5 days and 5 nights and did not waste any Kerosin. This astonishing performance shows us that in the future air traffic with alternative energy can be operated. Unfortunately, this energy carrier is not yet realizable, because there are still too many difficulties and problems that experts face. For example, a passenger aircraft, such as the Boeing 747, with a total and required interior equipment, is at least 350 tonnes in weight. It would be extremely problematic, if not impossible, to attach enough solar cells to the aircraft so that it would still be airworthy (flugtauglich). Another problem would be the flight speed, because a solar-powered aircraft would reach a maximum speed of 69 kilometers per hour. This would be slower than a car or a train and the majority of the passengers would not want to accept such a travel speed. In addition, you can not fly with a solar airplane at a longer distance without landing and recharge energy. Solar aircraft such as Solar Impulse 2 rely on constant solar radiation. At night, the aircraft has to rely on its lithium-ion batteries, which also slows down the speed.

>Ideas: [www.solarimpulse.com]

3. Interview

1. What are the technical opportunities to reduce the airpollution? Is this also supported by the Government?

The pollutant issues are depending on the start weight of an airplane. The lighter an airplane is, the more kerosene can be saved. SWISS has modified, for example, her seats. They have substituted the heavy seatpolster with air cushion (Luftkissen) polster. With such airplane modifications a lot can be influenced. Today the airplanes in the civil aviation are driven completely by kerosene. If this energy source burns, it becomes carbon dioxide (CO2). From 1 tonne of kerosene there originate 3. 15 tonnes CO2, but also steam and embroidery oxide (Stickoxide). These gases change the climate. Besides, embroidery oxide influences the air quality in ground level.

2. Is it a concern for you to invest capital in the development so that the idea of the environment is promoted?

For the environment of tomorrow – the responsible contact with the environment is a part of the enterprise culture of SWISS. We exert ourselves for a lasting action compared with the environment of the next generation.

3. Shortly the CSeries has been phased-in (eingeflottet). Is environmental thinking also a fundamental requirement for choosing this aircraft?

New airplane types expel less CO2. SWISS continuously invests in a modern fleet. On the short and medium distance fleet 30 Bombardier CSeries will substitute the Avro RJ 100 fleets from summer 2016. Besides, between 2019 and 2022 SWISS will take up ten Airbus A320neo and five Airbus A321neo of the newest generation in her fleet and substitute with it for ten older airbuses A320 as well as for five airbuses A321. On the long-haul-flights six Boeing 777 will substitute the airbus A340 in 2016 . Three other airplanes of the type Boeing 777-300ER will be phased-in between 2017 and 2018 to the SWISS fleet.

4. In your opinion, is it possible to revolutionize aviation by using carbon neutral airplanes on the road network? Can it be realized in near future?

The problem is: In spite of the success of the Solar impulses of project it is unlikely, that the solar technology on an air liner, as a Boeing 747 can be applied. In comparison to the light Solar impulse 2 a Boeing 747 has a start weight (Startgewicht) of at least 350 tonnes, in spite of its relatively same span. It would be extremely difficult if not even impossible for engineers to add enough solar cells to an airplane which is difficult with the available technology. It could maybe be realizied in 50 years.

5. What changes in future will be for the airline industry and the passengers?

SWISS has drastically reduced her specific CO2 issues since 2003. Today specifically there are per 100 passenger kilometres just 20% less. To achieve this aim, SWISS has invested milliards in new airplane types, has placed on lighter materials, has improved flight processes and has used to capacity her flights better. On account of the higher efficiency in the fuel consumption, the absolute CO2 issues have risen since 2003 merely by 9%, although the number of passengers on Swiss flights has increased in the same period about over 50%.

6. Are these improvments associated with additional cost for the passengers?

No, rather less. In the airport rates emission fees are included, so if the neutral CO2 airplane will be introduced, these cost would be eliminated. In my opinion new fees could be established for solar technology.

[Interview made with an employee from the aircraft sector, January 2017]

4. CO2 Footprint Calculator

We would like to introduce you to this calculator. With it is possible to calculate your CO2 Footprint on a specific flightroute. Feel free to try this Tool out.

Link to the calculator: here

.

Cockpit impressions filmed by Praphat from circ-circ.

Unser Fazit

Dieses Projekt war sehr lehrreich und hat uns eine Menge Spass gemacht. Die grössten Probleme hatten wir bei der Textkürzung, da es beim Lebenszyklus und dem Solar Impulse Projekt viele wichtige Fakten gibt, welche man kurz und bündig hervorheben musste. Zudem haben wir den komplexen Umfang unterschätzt.

Team: Michael V. and Praphat I.

☷ See the project teams here »

☵ Some words about the contributions »

☴ Our sponsors and partners » (the-horse.education)

Dear Airplane Team

Everyone who is reading this will learn a lot about the life cycle of an airplane. Its really Informative. I liked the facts about SWISS, how they reduced their CO2 emissions since 2003 and a lot more stuff.

Keep up the good work!

Best regards,

Aaron B.

Dear Airplane Team

Thank you for your interesting contribution! I was able to learn some new Information and know better about the life cycle of an airplane. I especially like the CO2 footprint calculator. It would have been nice if you had done a survey.

Greets Isabella (cardboard packaging team)

Dear Airplane team,

Your contribution is very informative and I liked also the footprint calculator.

At the point of the manufacturing process your picture about the manufacturing location all over the world seems to be lost?!

In my opinion it is important that the production is based in more than one country because the economical concentration would be too big.

I have heard that a airplane has no end of life because every component can be exchanged and also a lot of small airlines are using older models from big companies.

It would be better if you write the conclusion as well in English because your whole post is in that language.

Best regards,

Dany

Dear Airplane-Team

Really interesting topic. We never thought about the LifeCycle for airplanes.

The tool to calculate your own footprints made us feel you have to overthink your CO2 consum and what you can do to reduce it! Your contribution include everything you need: selfmade drawing, selfmade picture, calculator and a short film. Nice to visit your article.

Greetings Gillian and Mara (Cheese-Team)